Looking for a reliable, sustainable injection moulding partner?

Get in touch with our expert team today to discuss how we can bring your product to life — on time, on budget, and to the highest quality standards.

Contact an expert →Our goal is to produce these parts quickly and efficiently so you can get your products to market on time.

We are committed to sustainability, operating as a carbon neutral, zero waste to landfill facility, and specialise in the use of post-consumer recycled plastics.

Our microprocessor-controlled injection moulding machines range from 10 tonne to 650 tonne. They are fitted with fully automatic robots to help ensure process consistency and maximise efficiency.

This combined with lean manufacturing techniques used by our team of skilled technicians and engineers means we can increase productivity, reduce cost and ensure we develop the most cost-effective solution and process for our customers.

Our microprocessor-controlled injection moulding machines range from 10 tonne to 650 tonne. They are fitted with fully automatic robots to help ensure process consistency and maximise efficiency.

This combined with lean manufacturing techniques used by our team of skilled technicians and engineers means we can increase productivity, reduce cost, and ensure we develop the most cost-effective solution and process for our customers.

Over the past 30 years we have developed partnerships and a list of approved local and overseas toolmakers that are able to work to our stringent quality standards.

We work closely with our toolmakers to ensure we can offer highly competitive prices and lead times with the absolute best quality and service.

Our tooling validation process can ensure that all design aspects are considered to anticipate the final part, quality, profitability, and success of the project.

All customers tools receive preventive maintenance in our in-house tool room.

Regular monitoring and maintenance over the life of the mould is crucial to producing high quality injection moulded parts.

We utilise our computerised maintenance management software for automatic scheduling and to control assets and help ensure our customer’s tooling life is extended, and costs are reduced.

The quality control system at our injection moulding division guarantees the finished products we manufacture and deliver to our customers are of the highest quality and meet or exceed their intended expectations in the field.

We work closely with our customers and suppliers to integrate quality from product design through tool making to production and secondary operation such as printing and assembly.

To help strive towards manufacturing excellence our engineers and technicians are Six Sigma qualified and apply problem solving and quality improvement tools towards eliminating defects and improving efficiency.

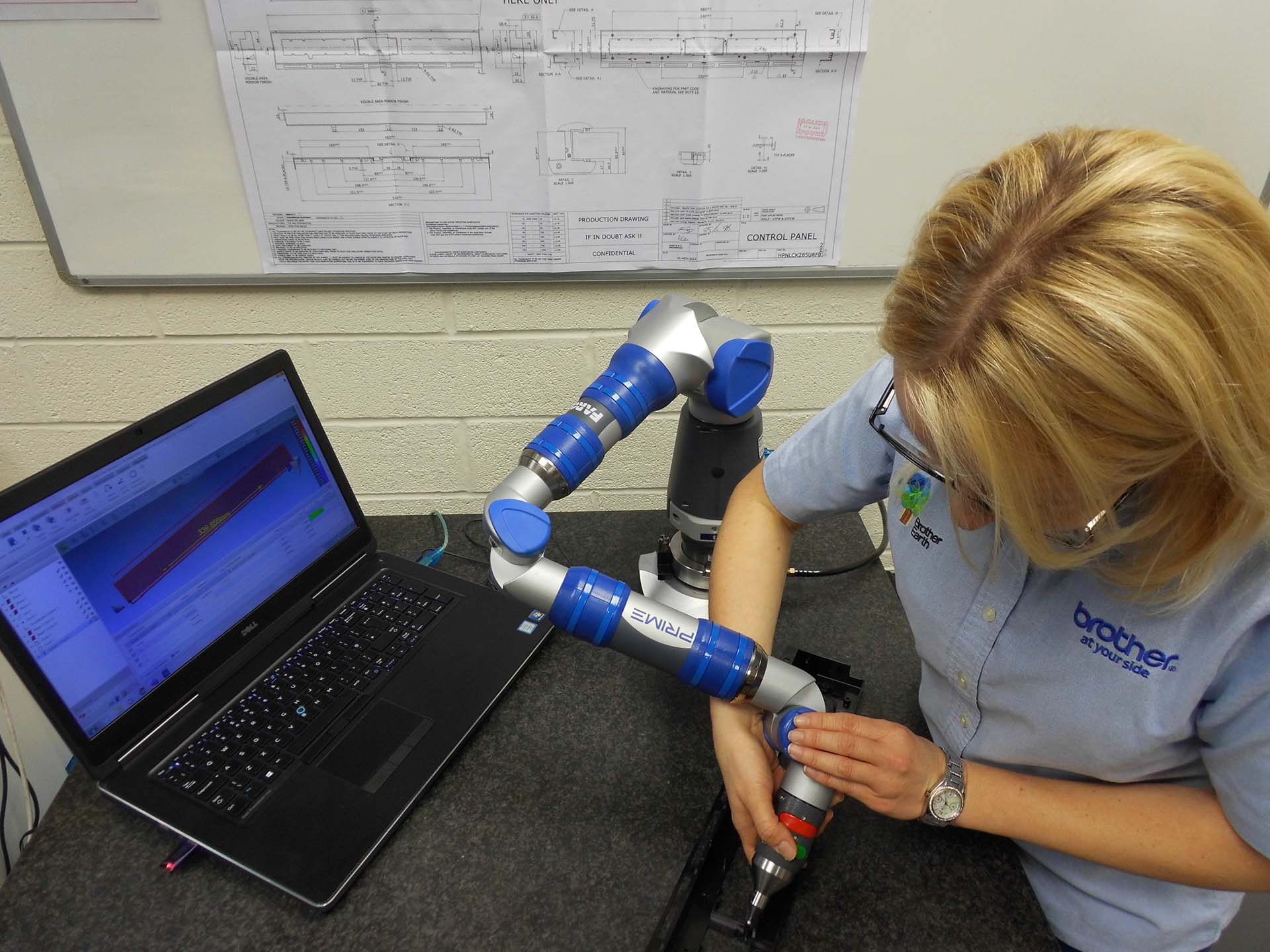

We understand the importance of meeting critical dimensional tolerance requirements for our customers and have the capability to measure the most demanding applications. We have invested in a comprehensive range of inspection equipment including Mitutoyo CMM, Faro Arm Portable CMM, GOM Scanner, variety of Smart scope OGP’s, and many more measurement gauges to ensure the reliability of our quality data.

We understand that every project comes with its own set of goals, challenges, and priorities. That is why we take the time to get to know our clients, what they are aiming to achieve, the obstacles they’re facing, and what they need us to do to help contribute to their growth and profitability.

Quality is a top priority. We thoroughly check all parts before they leave our sustainable injection moulding company UK facility to ensure they meet your standards and any necessary industry regulations. The tests we conduct include visual inspections and functionality assessments. We also use tools to spot any defects that could affect the safety or performance of the parts we manufacture.

We’re always looking for smarter, more efficient ways to improve how we work. From reducing and reusing excess materials to upgrading our technology, our goal is to offer cost-effective, sustainable, and quality solutions for each client. We're committed to keeping turnaround times short and costs down as well as doing our bit for the environment.

Find out more about Brother’s Quality approachLet’s build something brilliant together.

Contact us today to get started on your next injection moulding project.

Whether you need high-precision parts, tooling, or full-scale production support, our experienced team is ready to help.

Request a quote →